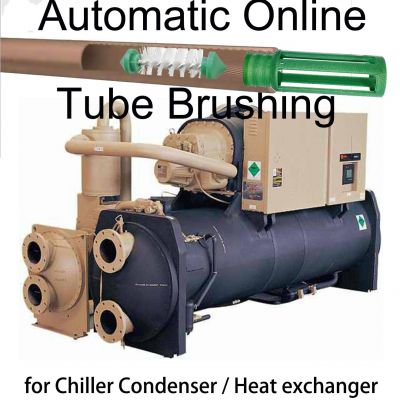

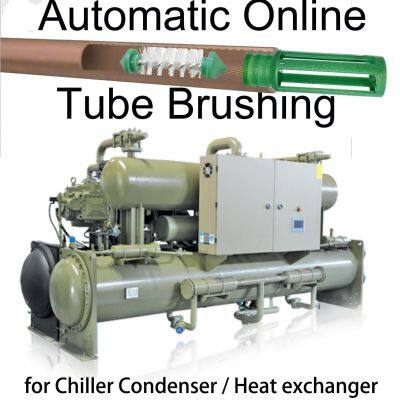

Automatic tube brush on-line cleaning system

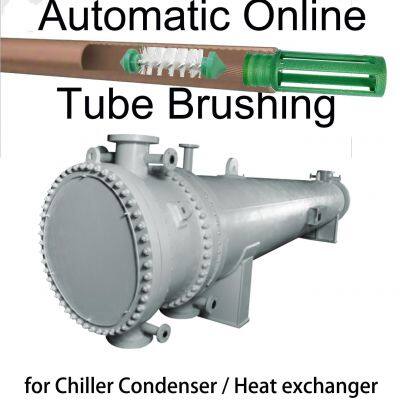

The automatic tube brush on-line cleaning system allow the chiller’s condenser tubes to be cleaned without chiller shut off, avoid the scaling and dirt build up on the inner wall of the heat exchange tube, keeps the the system run with optimal heat exchange efficiency and long-term energy saving.

The brush cleaning system components include cleaning brushes, brush catching baskets, water flow reversing valves, electric actuators, control panel.

Cleaning brushes: nylon bristles and stainless steel winding wire, the brush can withstand a temperature of 100 degrees Celsius, and can be applied to urban water, groundwater, surface water and salty seawater without corrosion and rust. As a wear part, the service life is 5 years (it is generally recommended to use 3 years for a detailed check whether it needs to be replaced, and the special use environment can be made according to the use of special materials)

Catching basket: made of PE, acid and alkali resistance, organic solvent resistance, good electrical insulation, can be applied to the water temperature environment from -20 to 70 degrees Celsius.

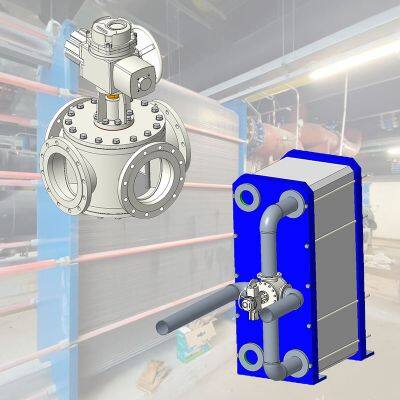

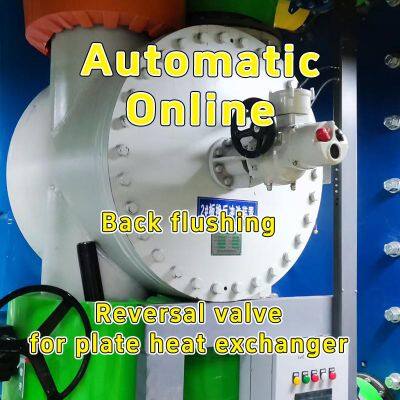

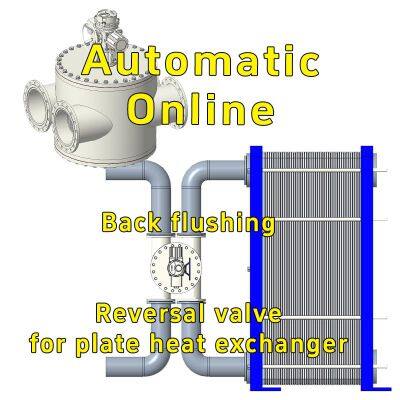

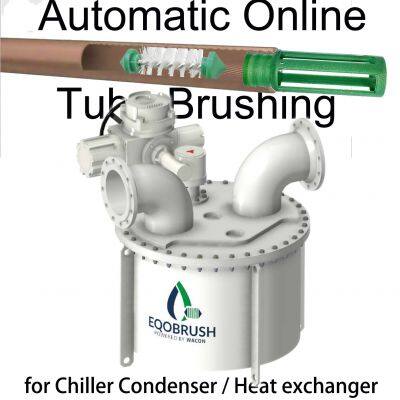

Reversal valve: made according to the standard of pressure volumetric device; SS400 is used for valve body and swing box; S45C is used for shafts and keys; The bearings are made of bronze; Protective slides: Teflon and other rubber seals. The applicable pipe diameter range is from 100-600 mm, can bear the standard water pressure of 1.0Mpa, the nominal flow rate is from 50 cubic meters / hour to 300 cubic meters / hour, and stainless steel can be selected according to the actual operation situation and water quality.

Electric Actuator: It is a heavy-duty industrial design actuator with a micro switch that records the position of the running trajectory and provides power for the commutation in a short time.

Control Panel: Configurable from 15 minutes to 24 hours of cleaning cycles, IP54 rated electrical box also includes: position indication, alarm indication, cycle counter, cable connector, etc. The cleaning unit operates completely independently and does not cause any disturbance to the refrigeration system.

The installation location of the brush cleaning

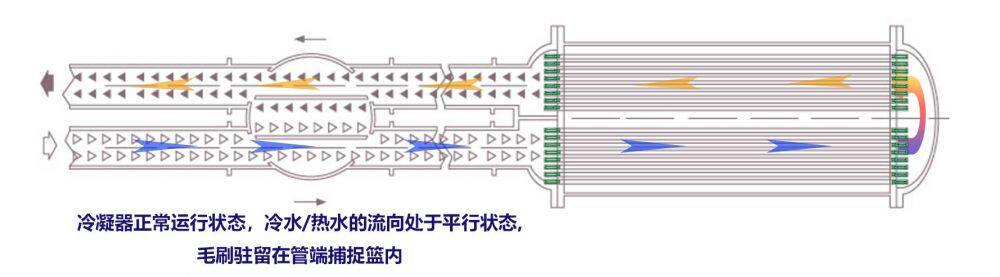

The basket is mounted at both ends of the bundle and is held in place with a special adhesive, while the brush is placed in the basket. The reversing valve is installed on the circulating water line in front of the condenser.

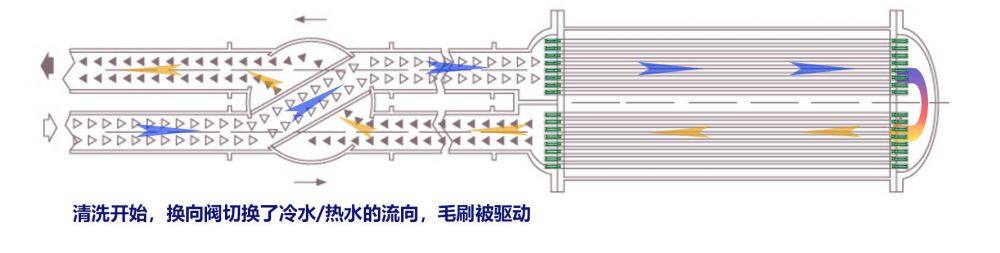

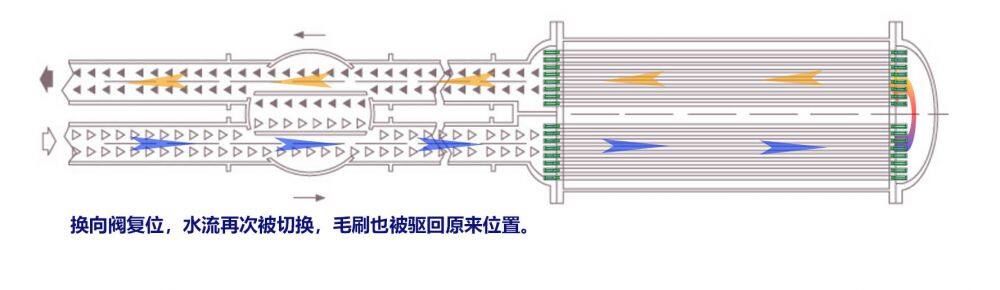

The working principle of brush cleaning system

When the cleaning device reaches the cleaning time, the swing box in the reversing valve automatically connects the cold water pipe to the hot water pipe through the drive of the actuator, causing the water flow direction in the condenser pipe to change, and under the drive of the water flow, the brush is washed away from the capture basket to reach the capture basket at the other end of the pipe bundle, during which all the accumulated dirt or the scale layer about to be formed on the inner wall of the pipe bundle is broken; At this point, the reversing valve is activated again, the water flow in the condenser returns to its original direction, and the brushes are brought back to the original capture basket. The dirt and debris that are broken up will enter the filtration system with the circulating water. At this point, a simple cleaning cycle has been completed and the formation of the scale layer has been successfully stopped.

Features of the operation of brush cleaning system

High cleaning efficiency

Each tube bundle is served by a single cleaning brush with two capture baskets; Mandatory cleaning of each tube.

Short cleaning time

The optimized design of the condenser brush cleaning system allows it to switch directions in just 10-15 seconds when switching between water flows. 4-6 times a day only takes a few minutes.

Chemical-free cleaning

Since cleaning takes place before the fouling is formed, all cleaning processes do not require the use of any chemicals. It avoids the corrosion of chemicals on the inner wall of the pipe bundle and excludes the possibility of discharge of residual waste chemicals, which is a measure of positive significance for environmental protection.

Hands-free

The operation of all cleaning cycles can be pre-set, and the system runs automatically, during which no one operates; The online monitoring system can also be used according to actual needs to grasp the status of the unit operation in real time.

Extremely low power consumption

As mentioned above, the total cleaning time of the brush cleaning system is only a few minutes per day, and if the unit is running for 360 days without downtime, the power consumption required for the cleaning cycle is 18 kW/h

The service life of the device

The cleaning brush can last for 5 years as a consumable material (3 years is recommended for replacement in poor water quality environments), and other components can be used for more than 20 years, covering the entire service life of the chiller.

Recently Posted

-

Protect Your Investment: Extend Chiller Life with Automatic Cleaning

December 25, 2025Condenser fouling doesn't just waste energy; it destroys your capital equipment. Scale buildup leads to under-deposit corrosio Read More

Read More -

No More Downtime: Online Cleaning for Continuous Operation

December 24, 2025Planned shutdowns for condenser cleaning disrupt production, compromise building comfort, and incur significant labor costs. The E Read More

Read More -

Stop Energy Waste: How 1mm of Fouling Increases Chiller Power by 30%

December 24, 2025Stop Energy Waste: How 1mm of Fouling Increases Chiller Power by 30%A mere 1mm layer of scale inside your condenser tubes acts as Read More

Read More -

Say Goodbye to Chemical Cleaning: The Automatic Tube Cleaning Solution

December 24, 2025Say Goodbye to Chemical Cleaning: The Automatic Tube Cleaning SolutionChemical cleaning for condensers is a reactive, costly, and Read More

Read More