Plate Heat Exchanger Backwashing

Technical Overview of Plate Heat Exchanger Backwashing Devices: Principles, Characteristics and Applications

I. Core Concept: Industrial Application of Dynamic Cleaning Technology

Plate heat exchangers (PHEs) achieve heat exchange between fluids through metal plates, widely used in refrigeration, chemical, energy and other fields. During operation, suspended solids, microorganisms and minerals carried by fluids easily deposit in low-velocity areas between plates, forming a fouling layer with low thermal conductivity. This leads to reduced heat transfer efficiency and increased energy consumption.

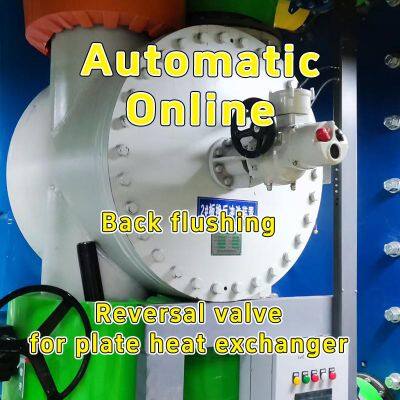

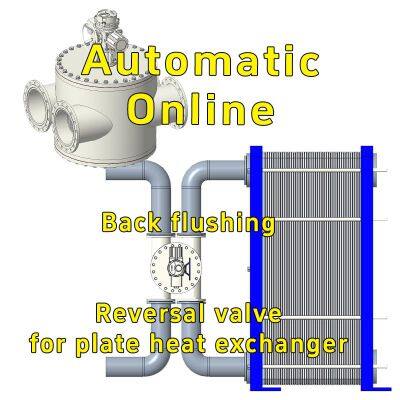

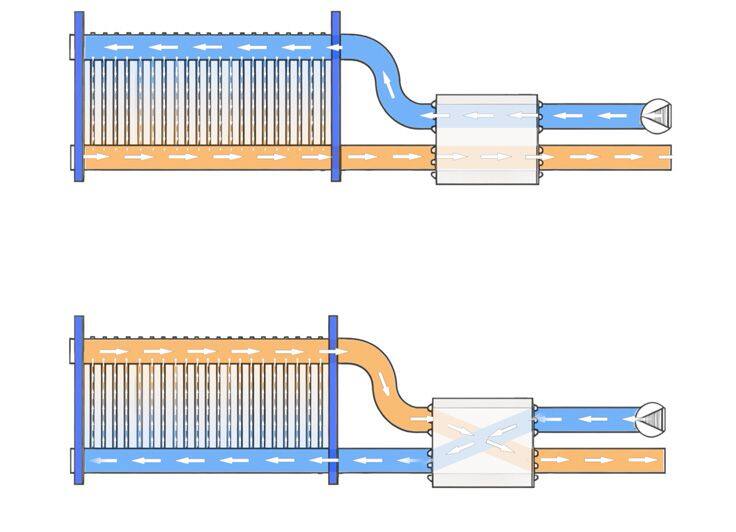

The backwashing device is an automated cleaning system integrating diverter valves and control systems. It periodically reverses fluid flow to flush the water channels in heat exchange plates using hydrodynamic energy, removing fouling before it hardens. This technology enables online cleaning without shutdown or disassembly, shifting from reactive maintenance to proactive anti-fouling.

II. Technical Characteristics: Integration of Automation and Efficient Cleaning

Online Operation Mechanism

The device activates the diverter valve according to a preset program (e.g., every 4 hours), reversing fluid flow for 30-60 seconds. High-velocity flow scours the original low-velocity deposition areas, discharging fouling particles with the fluid.

Pure Physical Cleaning Mode

Fouling is removed via fluid dynamics principles, eliminating the need for chemical agents. Compared with traditional chemical cleaning, it reduces reagent usage by 90%, avoiding equipment corrosion and wastewater treatment costs.

Low-power Design

The core diverter valve has a pressure loss ≤0.1 bar, and electric actuators consume 0.25-2.2 kW. Annual energy costs are 85% lower than manual cleaning.

III. Practical Advantages: Quantified Economic and Efficiency Improvements

Cost Optimization

Backwashing reduces cleaning frequency by 50-80%, significantly cutting labor and consumable costs.

Efficiency Maintenance

Continuous cleaning maintains the heat transfer coefficient above 95% of the design value.

Equipment Life Extension

Avoiding mechanical damage to seal gaskets from disassembly extends the overall service life of equipment.

IV. Equipment Composition: Modular Design for Diverse Scenarios

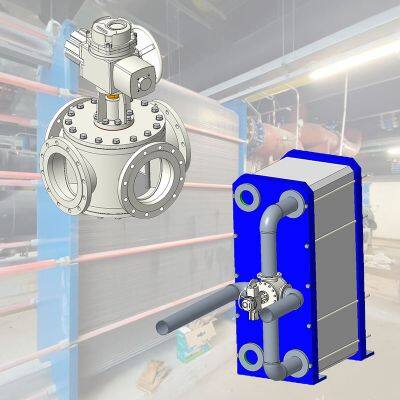

Diverter Valve Types and Parameters

KV Swingbox Valve (patented design): Mild steel/304 stainless steel body, suitable for DN200-DN600 pipes, pressure loss 0.05-0.1 bar, ideal for space-constrained setups.

KX Four-way Ball Valve: Cast iron body + 304/316 stainless steel ball, suitable for DN80-DN600, pressure rating 1.0-2.5 MPa, preferred for small-diameter pipes.

KH Straight-through Valve: Carbon steel body, suitable for DN150-DN600, linear flow path reduces pipeline modification, fit for spacious installations.

Control System

Integrated with PLC intelligent modules, it real-time monitors heat transfer efficiency via temperature difference sensors (accuracy ±0.5℃)

V. Application Fields and Scenario Adaptation

Commercial Buildings: Central air conditioning water systems in offices and hospitals, maintaining cooling efficiency and reducing maintenance labor.

Industrial Manufacturing: PHEs in petrochemical reaction units and food sterilization equipment, preventing fouling from affecting process stability.

Energy Sector: Seawater cooling systems in nuclear power plants and district heating stations, maintaining heat transfer performance under high-hardness water conditions.

Refrigeration Sector: Evaporators/condensers in cold storage and refrigeration units, avoiding biological fouling from impacting cooling capacity.

By combining fluid dynamics with automation control, this technology provides sustainable cleaning solutions for industrial heat exchange equipment, achieving dual value optimization in energy saving and equipment maintenance.

Recently Posted

-

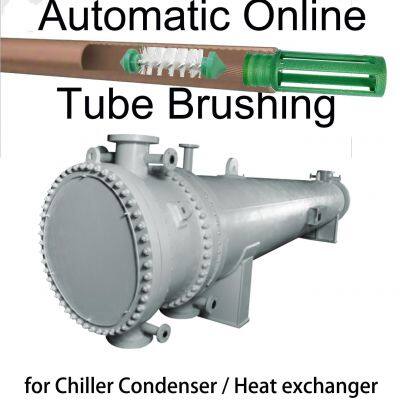

Protect Your Investment: Extend Chiller Life with Automatic Cleaning

December 25, 2025Condenser fouling doesn't just waste energy; it destroys your capital equipment. Scale buildup leads to under-deposit corrosio Read More

Read More -

No More Downtime: Online Cleaning for Continuous Operation

December 24, 2025Planned shutdowns for condenser cleaning disrupt production, compromise building comfort, and incur significant labor costs. The E Read More

Read More -

Stop Energy Waste: How 1mm of Fouling Increases Chiller Power by 30%

December 24, 2025Stop Energy Waste: How 1mm of Fouling Increases Chiller Power by 30%A mere 1mm layer of scale inside your condenser tubes acts as Read More

Read More -

Say Goodbye to Chemical Cleaning: The Automatic Tube Cleaning Solution

December 24, 2025Say Goodbye to Chemical Cleaning: The Automatic Tube Cleaning SolutionChemical cleaning for condensers is a reactive, costly, and Read More

Read More